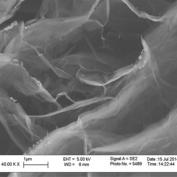

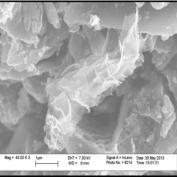

Graphene has been attracting great interest due to its extraordinary electronic, thermal, and mechanical properties, resulting from its two-dimensional structure, and to its potential applications such as energy, wind turbines, construction, defence, automotive, aeronautics and aerospace applications. In last decades, there are numerous works about graphene synthesis and its applications in laboratory scale but mass production of graphene has still doubts and obstacles. One of the applicable methods is graphite oxidation to reduce the strong bonding between graphene sheets in graphite and obtain single layer graphene. In the present work, graphene nanosheets were produced in pilot scale by improved, safer and mild chemical route. The proposed technique provided to reduce the average number of graphene layers steadily from 105 in the raw graphite to 20-25 in graphene nanosheets by stepwise chemical procedure. Additionally, graphene obtained from recycled carbon source was a scalable, cost effective and environmentally friendly. After the production of high quality and high quantity graphene, graphene based composites were produced by using different thermoset and thermoplastic polymers. The mechanical and thermal properties of the materials were improved and significant weight reduction was provided by the addition of graphene in matrix material in low loadings changing from 0,05 to 5%. As a result, more reliable and long lasting composite production is possible by using graphene in polymer composites.

This project is granted by Tubitak 1512 Multiphase Entrepreneurship Grant Program. Co-founders of Nanografen Co: Dr. Burcu Saner Okan, Prof. Dr. Yusuf Menceloglu and Inovent A. S.)