Functional polymer thin films find uses in wide range of energy applications as separation membranes for fuel cells or as electrodes in batteries. Low costs, flexible nature and tailored functionalities make the polymer thin films better alternatives compared to their metal counterparts. Our research efforts focus mainly on conductive polymer thin films and selectively permeable ultra-thin functional polymers.

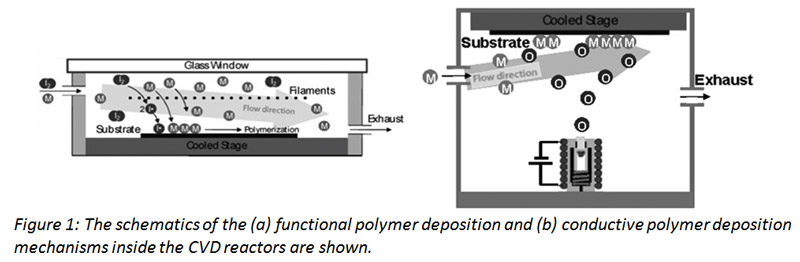

Synthesis of the ultra thin polymer films is achieved by chemical vapour deposition technique where the precursors are introduced to a deposition chamber in vapour phase. For the synthesis of the functional thin films, vapour phase radicals are used to initiated the polymerization reaction on the substrate surface by reacting with the vinyl bonds of the adsorbed monomers. Peroxide-based initiator precursors are used to form the radicals through thermal decomposition upon contact with heated filaments. The conductive polymer films on the other hand are synthesized via the reaction of oxidant molecules with adsorbed monomers forming conjugated polymers. Depending on the monomer-oxidant pair used the doping takes place either during polymerisation reaction or post-processing.

The low substrate temperatures and chamber pressures used during the deposition process enable coating of delicate substrates such as paper or textile. Furthermore, the thickness of the polymer coatings can be controlled in the nm-level, thus ultra-thin layers of polymers can be coated. As the polymerisation occurs on the substrate surface and the precursors are in the vapour phase, conformal coatings of high aspect ratio structures or rough surfaces can be coated homogeneously.

The chemical composition of the polymer thin films can be controlled by varying the precursor ratios and the system parameters, such as the substrate temperature and chamber pressure which control the precursor concentration on the substrate. The decoupling of the system parameters and separate control of the film thickness enable fine-tuning of the chemical and physical properties of the polymer thin films according to the applications.

Functional Polymer Thin Film Membranes:

Our polymer thin film membrane studies focus on fabrication of free-standing ultra thin polymeric membranes for controlled diffusion and selective permeation of model molecules. The polymer coatings are deposited on sacrificial layers which are subsequently etched to release the free-standing polymer layers. These permeation characteristics of the polymer membranes are then tested under different flow and pressure conditions. The selectivity and the permeability of the membranes can be controlled by tuning the mesh size and the exposed functional groups of the polymer coatings. Mainly hydrogels with different crosslink densities are used to study the effect of mesh size. Poly(hydroxyethyl methacrylate) and poly(N-isopropyl acrylamide) are examples to the functional polymers studied. The effects of the mechanical properties of thin films are studied using membranes of glassy and rubbery polymers, such as poly(butyl acrylate) or poly(dimethyl siloxane).

Free-standing copolymer films with carboxylic acid and fluorocarbon groups are also studied with potential applications as proton exchange membranes for fuel cells. The concentrations of the monomer precursors are varied and the effect of the composition on the conductivity is investigated. The carboxylic acid group concentrations in the polymer, which affect the proton conductivity of the membranes, in addition to the swelling ratios, can be tuned by varying the precursor concentrations. This enables tuning of polymer properties for improved proton conductivities.

Conductive Polymer Thin Films and Nanostructures:

Our studies on conductive polymer thin films focus mainly on depositions of conjugated polymers that are doped during deposition or post-deposition for improved conductivity. The effects of deposition conditions, such as substrate temperature or precursor flow rates, on the composition of the conjugated polymers are investigated. The surface roughness of the thin films which is related to the deposition rate can also be adjusted. Thin films of polyaniline, polypyrrole and polythiophene polymers as potential electrode materials are studied and the relation between their deposition conditions and conductivity is investigated.

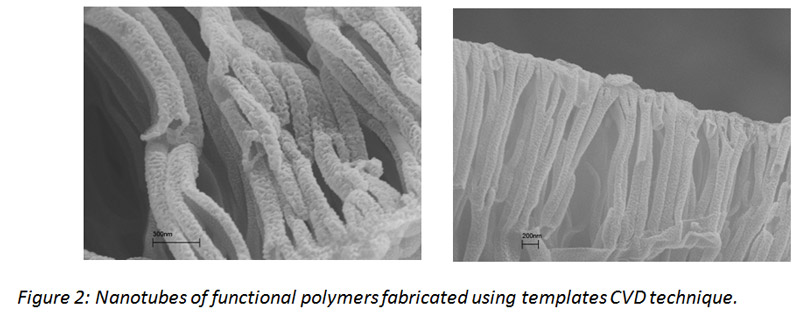

Control of the deposition rate is crucial for conformal deposition of thin films on patterned surfaces. One major part of our research efforts focus on fabrication of polymeric nanotubes. The nanotubes are formed by depositing polymer thin films inside the pores of a track etch membrane and subsequently etching the membrane away to release the nanotubes. This way nanotubes of different functionalities and physical properties could be formed. While these nanostructures can be used for controlled delivery applications upon triggering, conductive nanostructures can also be used in energy storage applications due to their large surface-to-volume ratios and high densities.

These projects are supported by the following grants:

- Development of Smart Composite Membranes For Molecular Separation Applications, TÜBİTAK 3501.

- Fabrication and Characterization of Coaxial Conducting Polymer Nanotubes for Molecule Storage and Controlled Release Applications, TÜBİTAK 1001.