The need for novel nanoparticles is a wide con-cern of scientific community. But the ways of producing of these extraordinary properties is another concern. Different methodologies and processing techniques are used for manipulating the properties of nanoparticles in atomic dimensions. Most of them came with the same conclusion:

“It is obligatory to prevent the agglomeration of nanoparticles for size control and distribution.”

The most efficient and universal way to overcome these problems is to use polymer-assisted fabrication of inorganic nanoparticles and hybrid polymer–inorganic nanocomposites. Electrospinning is a versatile method that will satisfy the primary needs for the in situ synthesis of nanoparticles within a polymer matrix. The very basic nature of the nanofibers produced by electrospinning i.e. very large surface area to volume ratio, flexibility in surface functionality, and superior mechanical performance compared with any other known form of the materials makes it the best choice for maneuvering nanoparticle properties.

The aim of this work was to suggest an alternative way for synthesizing nanoparticles through the electrospinning process. By maneuvering the macromolecular architecture of chosen polymers, we mediated to the controlled synthesis of nanoparticles.

Electrospinning parameters were discussed in detail throughout this research. The change of polymer concentration and solution conductivity affected resulting fiber diameters. Fiber diameters increased with polymer concentration and addition of extra metal salts into polymer solutions favored in the formation of more uniform and thinner fibers.

By appropriately choosing reduction solvents and heat treating cycles, enhanced control of nanoparticle sizes at different reduction mediums and temperatures was achieved on different processing conditions.

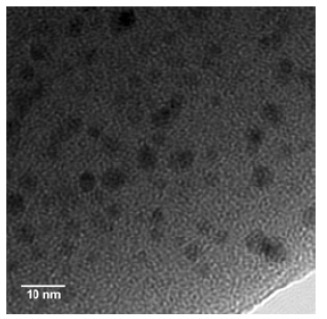

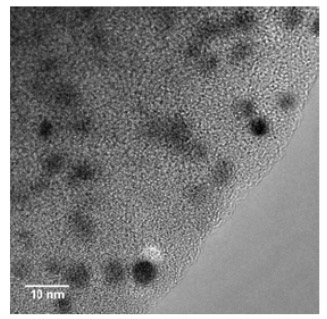

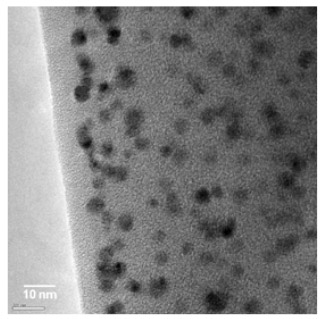

The results of this study showed that choosing an appropriate polymer template would determine the size and distribution of nanoparticles. Synthesized blocky-copolymers of acrylonitrile with acrylic acid, vinyl phosphonic acid 2-acrylamido-2-methylpropane sulfonic acid yielded agglomerated nanoparticles. The change of polymer architecture to a random structure poly(acrylonitrile-co-n-vinyl pyrrolidinone), the size of nanoparticles could be reduced to several nanometers. Effective control of macromolecular design by altering the copolymer structure enabled the size tuning for nanoparticle crystals.

By the application of methods proposed in this research it was possible to confine sub 10nm’s nanoparticles with uniform distributions through-out the fiber structures even at elevated temperatures. Rather than other literature findings, nanoparticles could be generated even at order of 2-5 nm at 600°C, and 10-17 nm at 1000°C, which were the smallest among the similar researches.

The catalytic activities of metal nanoparticles on carbon nanofibers showed an electroactive active surface area of 34,6 m2/g for Pt and 22.4 m2/g for Pd. These results confirmed the viability of use of metalized nanoparticles on carbon nanofibers as catalysts for fuel cell applications.

These results proved the concept of this research that by selectively choosing the processing conditions and the production techniques, generation of nanoparticles in uniform and smaller dimensions was possible.