Biosafety cabinets (BSC) are intended to protect the user from hazardous aerosols and are equipped with high efficiency particulate air (HEPA) filters that frequently recirculate air back into the lab. They are not capable of capturing hazardous gases and their baffles and inner workings are not generally chemical resistant. Using a BSC with a hazardous gas could not only ruin the cabinet, but it could result in injury to the user. Proper use of BSCs is described in the Biological Safety section.

Laminar flow hoods (LFHs) are work benches that continuously bathe the work area with clean, filtered air. Their primary purpose is to protect whatever is being worked on, or “product”, not the user. Some laminar flow hoods are also chemical benches which protect both the user and the products. These benches expel air via an exhaust ventilation system and do not recirculate it back into the lab.

Biosafety cabinets (BSCs) and laminar flow hoods are serviced and certified by a contracted vendor. Problems with BSLs or LFHs should be reported to the LS/LSS.

Local Exhaust Ventilation

People who have a need for local exhaust ventilation should contact LS/LSS for an evaluation to determine what type of system will work best for their process. Various forms of local exhaust ventilation are seen in Sabancı University labs and may have been designed and installed for specific processes. These include:

Elephant Trunk

Elephant trunk (Figure 4.3.a) is useful for small sources of emissions.

Figure 4.3 Elephant trunk (a), canopy (b), slot and plenum (c)

(Courtesy of Dekolab)

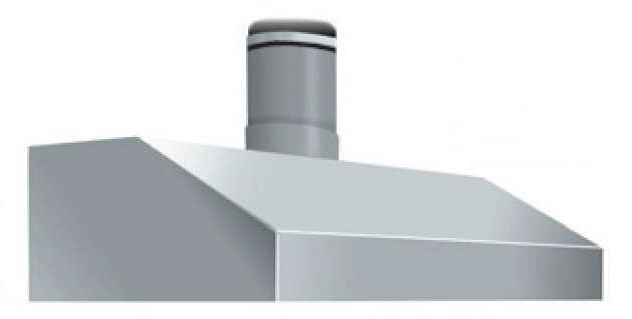

Canopy

Canopy (Figure 4.3.b) is useful for hot operations or to exhaust materials that are lighter than air.

Slot and Plenum

Slot and plenum (Figure 4.3.c) are useful for heavy vapors or particulates because they pull the contaminant backwards, away from the user, into the plenum before exhausting it up and out.

Glove Boxes

Glove boxes (or gloveboxes) are sealed container design to protect the user, the process or both. They usually includes at least one pair of gloves attached to the container. The user handles the materials inside using the gloves. Typically, a glove box has an antechamber that is used to materials transfer.

Configuration of the glove boxes depends on the application. Glove boxes can be under vacuum or positive pressure. Glove boxes under vacuum are designed to protect the operator and ambient environment from the materials or processes; glove boxes under positive pressure are intended to provide an inert atmosphere for the materials or processes. The glove box environment may be inert (e.g. nitrogen, argon, helium), sterile, dry, or otherwise controlled. Some glove boxes are equipped with filters (e.g. HEPA) while others vent to a fume hood duct or a dedicated duct. Various controllers, sensors and equipment such as pressure gauges, oxygen sensors, temperature controllers and purifiers could be attached to the glove box.

The term “glove box” is most often applied to containers used in chemical and electronic laboratories. Similar apparatus is present in pharmaceutical and biological applications. In biological applications, Class III biological safety cabinets are similar to glove boxes. A Class III cabinet is sealed with a non-opening window, gas tight, and manipulation is made through attached gloves. This cabinet enable to work with high risk agents and maximize the protection level for the operator and the environment. Box environment is HEPA-filtered and the air drain must be filtered through two HEPA filters. Negative pressure in the cabinet maintained by an independent, dedicated exhaust structure maintains airflow

A glove box should have maintenance and be inspected regularly to sustain its protection level for both sides. Manufacturers and regulatory recommendations about inspection and maintenance should be routinely implemented. Glove boxes which are dedicated to hazardous chemicals or processes are exempted from the routine inspection.

Another important and possible source of contamination risk is the glove boxes. These elements are particularly vulnerable. Gloves should be routinely examined for cuts, tears, cracking and pinhole leaks. If the gloves are defective, the gloves should be immediately changed. Glove box gloves also vary according to the application such as thickness, material, etc. Choose the right one for the glove box and application.

There are several tests that can be achieved on glove boxes, depending on the glove box and the application such as pressure decay (for positive pressure), rate of rise (for negative pressure), oxygen analysis, containment integrity, ventilation flow characterization, and cleanliness. Leakage can be identified using a mass spectrometer leak detector, ultrasound, the soap bubble method or use of an oxygen analyzer.

Safety Shields

Safety shields, such as the sliding sash of a fume hood, are designed to protect the personnel from sudden spattering or explosion release of highly concentrated acids, bases, oxidizers or reducing agents: Base requirement for reactions performed at vacuum or high pressure is safety shields. In addition to this, alteration of experimental procedure such as scaling up or first time experiment should also performed behind the safety shield.

Ventilated Storage Cabinets

These are cabinets (Figure 4.4) which are fitted with forced ventilation. They may be free-standing with their own extract system, or may be situated beneath a fume cupboard and attached to its duct. They are designed to safely store chemicals that give off noxious fumes and smells. These fumes are sucked away by the forced ventilation.

Ventilation of chemical storage cabinets may only be accomplished with prior approval by LSS.

For appropriate storage requirements of a particular chemical, please see ChemWatch.

cabinet suitable for combustible chemical storage (right) (Courtesy of Dekolab)

Compressed gas cabinets

Highly toxic or odorous gases should be used and stored in gas cabinets (Figure 4.5). In the event of a leak or rupture, a gas cabinet will prevent the gas from contaminating the laboratory.

Gas cabinets should be connected to laboratory exhaust ventilation using hard duct, rather than elephant tubing, since such tubing is more likely to develop leaks. Coaxial tubing should be used for delivering gas from the cylinder to the apparatus. Coaxial tubing consists of an internal tube containing the toxic gas, inside another tube. In between the two sets of tubing is nitrogen, which is maintained at a pressure higher than the delivery pressure of the toxic gas. This ensures that, in the event of a leak in the inner tubing, the gas will not leak into the room.

References and sources for information from the relevant websites and documentation of different universities, NGOs and government agencies used in the preparation of this website are provided at references.