Energy Efficiency with pHEMA Coated Surfaces

Recently, the size of fluidic systems is shrinking from macro to micro size leading to more compact systems. Such emerging microfluidic systems find many applications in many areas such as electronics cooling, chemical reactors, micromixers, biotechnology, drug delivery, micropropulsion, and fuel cells. Due to their extensive use and need, heat and fluid flow in such microfluidic systems attracted attention of many scientists, so that many studies were performed in this promising field.

First generation microfluidic systems consisted of plain microchannel configurations. Heat and mass transfer and fluid flow in such plain microchannel systems have been extensively studied in the last decade. Although there remain still many issues with plain microchannels, the state-of-the-art knowledge in the field is such that the heat transfer community is ready to face new challenges. Moreover, there is a strong need for more sophisticated second generation microfluidic systems to have a better performance. This project addresses this lack of information about second generation microfluidic systems having microchannels with modified surfaces.

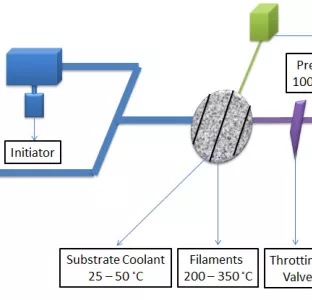

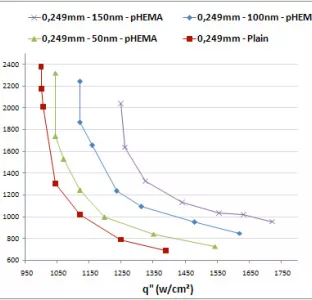

Flow boiling in mini/microtubes was investigated with surface enhancements provided by crosslinked polyhydroxyethylmethacrylate (pHEMA) coatings, which were used as a crosslinker coating type with different thicknesses (~50 nm, 100 nm and 150 nm) on inner microtube walls. Flow boiling heat transfer experiments were conducted on microtubes coated with crosslinked pHEMA coatings. pHEMA nanofilms were deposited with initiated chemical vapor deposition (iCVD) technique. De-ionized water was utilized as the working fluid in this study. Experimental results obtained from coated microtubes were compared to their plain surface counterparts at two different mass fluxes (5.000 kg/m2s and 20.000 kg/m2s), and significant enhancements in Critical Heat Flux (up to 29.7 %) and boiling heat transfer (up to 126.2 %) were attained. iCVD was proven to be a very practical method for pHEMA coatings in micro scale channels/tubes.

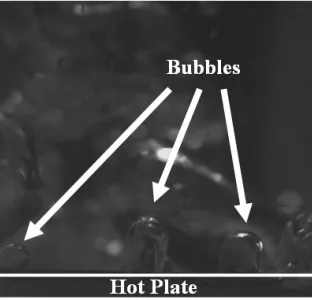

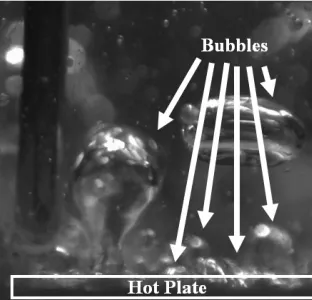

Crosslinked pHEMA coating improves boiling heat transfer performance and increases the energy efficiency since it increases the nucleation site density by offering more active nucleation sites due to its porous structure, raises bubble generation frequency from the surface, and improves liquid replenishment to the surface after bubble departures. pHEMA coatings could improve boiling heat transfer for micro scale cooling applications, where enhancement may be not possible with common surface enhancement and microfabrication methods.

References

Cikim, T., Armagan, E., Ozaydin-Ince, G., and Koşar, A.," Flow Boiling Enhancement in Microtubes with Crosslinked pHEMA Coatings, Having Different Coating Thicknesses" Journal of Heat Transfer, 136, 081504, 2014.

Kaya, A., Demiryurek, R., Armagan, E., Ince, G., Sezen, M., and Koşar, A., “The Boiling heat transfer enhancement in mini/microtubes via polyhydroxyethylmethacrylate (pHEMA) coatings on inner microtube walls at high mass fluxes,” Journal of Micromechanics and Microengineering, 23, 115017, 2013.